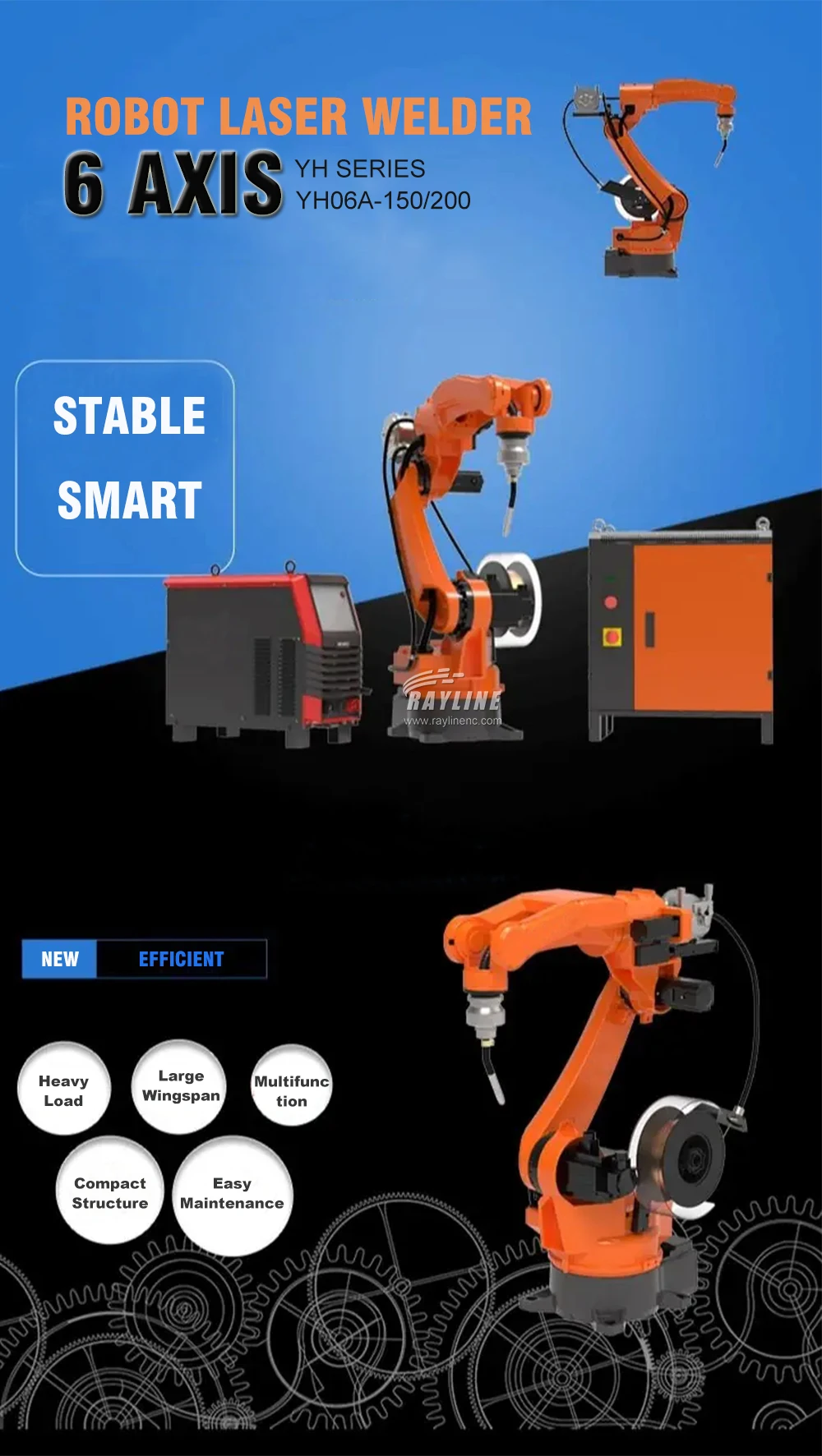

Automatic Industrial 6 Axis Collaborative Robot Arm Spot Gantry Tig Mig Robot Arm Laser Welding Arm Robot Robotic Arm Welder

- Pre-Order Available (Estimated ±15 Day Delivery)

- 7 day unit replacement guarantee(Video Unboxing Required)

- Including shipping costs, sent by Supplyinx.com

- Pick up at a supplyinx.com collection point is possible

- 24/7Customer service

Description

- Hign-concerned Chemical: None

- Origin: Mainland China

- Brand Name: RANCLAI

- Is Smart Device: YES

- Usage: Laser welding carbon steel, stainless steel, aluminum, titanium ect.

- Certification: CE

- Wavelength: 1064NM

- Condition: NEW

- Laser Wavelength: 1064-1080nm

- Laser Welding depth of Fusion: 0.2-8MM

- Warranty: 2 Years

- After-sale: Online or Local service

- Packaging: Export Plywood

- Machine Language: English, Portuguese, Italian, Russian, French, German, Spanish, Polish, Korean, Turkish, Greek, Chinese, Czech, Japanese, Slovak, Thai, Vietnamese, Romanian ( Customized)

- HS Code: 8468800000

Product Introduce:

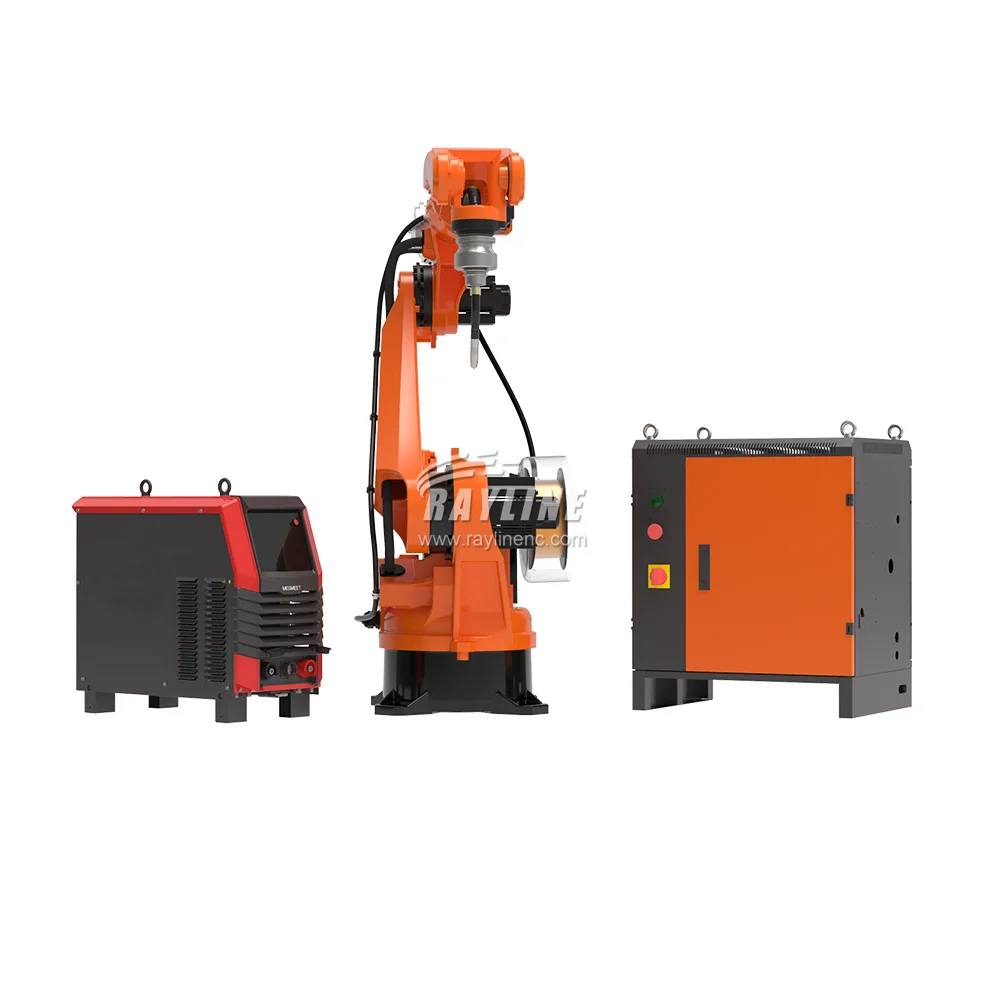

YH series welding robots are industrial robots engaged in welding (including cutting and spraying). Industrial robots belong to standard welding robots, which are multi-purpose, reprogrammable automatic control operating machines used in the field of industrial automation. In order to adapt to different purposes, the mechanical interface of the last axis of the robot is usually a connecting flange that can accommodate different tools or end effectors. The YH series welding robot is equipped with welding tongs or welding (cutting) guns on the end flange of industrial robots, enabling welding, cutting or thermal spraying.

Welding robots mainly consist of two parts: robots and welding equipment. The robot consists of a robot body and a control cabinet (hardware and software). And welding equipment, taking arc welding and spot welding as examples, consists of welding power supply (including its control system), wire feeder (arc welding), welding gun (pliers) and other parts. For intelligent robots, there should also be sensing systems, such as laser or camera sensors and their control devices.

Advantages:

1) Stabilize and improve welding quality, and be able to reflect welding quality in numerical form;

2) Improve labor productivity;

3) Improve the labor intensity of workers and enable them to work in hazardous environments;

4) Reduced the requirements for workers’ operational skills;

5) Shortened the preparation period for product modification and replacement, and reduced the corresponding equipment investment.

Parameters:

|

Model |

YH06A-150/200 |

|

Axis |

6 Axis |

|

Capacity |

3KVA |

|

Body weight |

170KG |

|

Rated payload |

6KG, 8KG, 10KG, |

|

Max range |

150CM, 200cm |

|

Repeatability |

±0.08MM |

|

IP Grade |

IP54/IP65(Wrist) |

|

Installation |

Ground,Ceiling |

|

Temperature |

0℃~45℃ |

|

Humidity |

20%-80%(No-Humidity) |

|

Vibration |

≤4.9M/S² |

|

Others |

No flammable and corrosive gases, liquids, away from electrical noise sources |

|

Machine Name |

Six-axis Robot |

|

Place of Origin |

China |

|

Warranty |

2 Years |

|

Applicable Industries |

Handling, welding, cutting, packaging, sorting, testing, medical surgery, scientific research, etc |

|

Machinery Test Report |

Yes |

|

Video outgoing-inspection |

Yes |

|

Laser wavelength |

1064nm |

|

Cooling System |

Waterand airCooled |

|

After Warranty Service |

Video Online Supportor local support |

|

Fiber length |

5m-10m |

|

Welding depth |

0.1 – 8mm |

|

Operating mode |

LCD Touch Screen |

|

Key Selling Points |

High efficiency, light and flexible |

1. Welding and machining: It can perform automated welding, cutting, milling and other processing tasks to ensure consistent product quality and high precision.

1. Welding and machining: It can perform automated welding, cutting, milling and other processing tasks to ensure consistent product quality and high precision.

2. Packaging and sorting: In the logistics and warehousing industry, robotic arms are responsible for packaging products and sorting goods, improving logistics efficiency and reducing labor costs.

3. Inspection and testing: Quality inspection and non-destructive testing of products using robotic arms, such as X-ray or ultrasonic testing, to quickly and accurately detect defects or anomalies.

4. Medical surgery: In the medical field, robotic arms are used to perform high-precision surgical procedures, helping doctors perform minimally invasive procedures, reduce risks and improve surgical success.

5. Work in dangerous environments: in extreme environments, such as nuclear power plants, deep-sea exploration, fire rescue, etc., robotic arms can replace manual work to ensure personnel safety.

6. Scientific research: In scientific laboratories, robotic arms are used to manipulate and handle experimental samples, perform precision measurements, and operate scientific equipment.

7. Handling and assembly: The robotic arm is capable of grasping, handling and placing parts to complete the assembly process of the product.

In addition, the industrial robot arm can also move objects or tools according to the requirements of spatial posture, perform various industrial operations, such as clamping welding pliers or welding guns, handling die-cast or stamping parts, laser cutting, spraying, assembling mechanical parts, etc.

Reviews

There are no reviews yet.